melt flow index testing|melt flow index table : distributors Explore the crucial role of Melt Flow Index Testers (MFI) in polymer testing. Learn how Pacorr's advanced solutions align with ASTM D 1238 & ISO 1133 standards for quality . WEB1 dia atrás · Free DWG viewing including cloud files. 30-day trial to create and edit. Use familiar AutoCAD drafting tools online in a simplified interface, with no installation required. Access, create, and update DWG™ files anytime, anywhere.

{plog:ftitle_list}

Doncaster racecard & betting odds from William Hill. Free Racing Post spotlight & verdict on all horse racing.

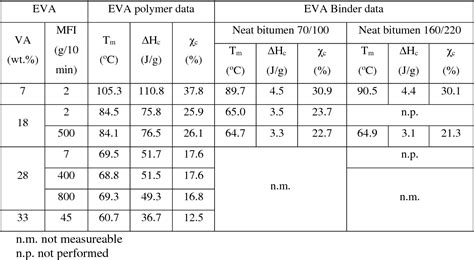

The melt flow index (MFI) or melt flow rate (MFR) is a measurement used to assess the flowability or melt viscosity of a polymer. It provides an indication of how easily a polymer can be processed through different processes. Explore the crucial role of Melt Flow Index Testers (MFI) in polymer testing. Learn how Pacorr's advanced solutions align with ASTM D 1238 & ISO 1133 standards for quality . Some of the common purposes for performing the Melt Flow Rate test are: Comparing materials for product development. Evaluating samples from new material .Melt Flow Index, Melt Flow Rate testing to ASTM D1238 or ISO 1133 Standards. Scope: Melt Flow Rate measures the rate of extrusion of thermoplastics through an orifice at a prescribed .

A polymer's Melt Flow Rate (MFR), or Melt Index (MI), is crucial for plastic processors and manufacturers. This measure indicates the polymer's flow capability, significantly influencing resin selection and production.The Melt Flow Index (MFI) refers to a characteristic used to assess the quality and flow properties of polymers. It measures the amount of material that can be deposited through a melt flow .Testing begins with chemists heating either virgin polymer pellets or ground finished product to a specified temperature, causing it to melt. They introduce this molten sample into our melt flow indexer, which uses a piston system to squeeze it through a minuscule aperture in a metal die for a specified period. Melt flow testing is simply a measure of the flow of a polymer when melted. The result of a melt flow test, called the melt mass-flow rate (MFR) or melt volume-flow rate (MVR), is defined as the amount of mass or .

The ASTM D1238 test method is used to determine the Melt Flow Index (MFI) of thermoplastic polymers. The ASTM D1238 MFI is a basic measurement for quality control and acceptance of incoming products. It is part of the ‘id’ of a polymer .

The MP1200 can be upgraded with optional features, including ISO 1133 tools and an encoder-based programmable piston displacement transducer (PPDT), for testing according to Procedures B & C (ASTM D1238) or for volume measurement tests (melt volume rate or MVR) and melt density calculations.Melt Flow Index, Melt Flow Rate testing to ASTM D1238 or ISO 1133 Standards. Scope: Melt Flow Rate measures the rate of extrusion of thermoplastics through an orifice at a prescribed temperature and load. It provides a means of measuring flow of a melted material which can be used to differentiate grades as with polyethylene, or determine the .The Melt Flow Index (MFI) or Melt Flow Rate (MFR) is a measure of the ease of flow of the melt of a thermoplastic polymer. Find out more. Close Search. Displaying - of results for . All Filter your results Products Applications Knowledgebase Video Standards News Events Industries Other. . Melt Flow Testing. Pharmaceutical.The MFi5 is a compact instrument that allows rapid inspection of the melt mass flow rate of plastics to Method A, Method B and Method C. It is especially designed for different needs, from simple Incoming Material Acceptance to Process Control checks. The manually operated MFi5 tests plastics quickly and reliably thanks to the pre-set methods.

Oxygen Vapor Transmission Rate Test System inc

Melt Flow Index tester play a pivotal role in assessing the flow characteristics of plastic materials under controlled conditions. This comprehensive guide delves into the technicalities of MFI testers, their importance in maintaining product quality, and how they comply with industry standards ASTM D 1238 and ISO 1133, with a particular focus on the instruments .

Compliance with melt flow index testing. Our ASTM and ISO compliant systems range from devices that perform simple manual tests through to semi-automated machines that can deliver multiple weight tests. We know how important it is to make sure you’re able to test to the standards demanded by your industry, that’s why we create solutions .Melt Flow Rate (MFR) or Melt Flow Index (MFI) is the flow measurement of polyethylene being pushed through a 2mm diameter die at 190°C with 2.16 kg mass. The result is expressed in grams per 10 minutes (g/10 min). Experimental Procedure Summary Approximately 6 to10 grams of polyethylene is loaded into the barrel of the melt flow plastometer . Rather, the melt flow index is an empirical value that is ultimately influenced by the conditions of the test. This article discusses the importance of MFI and delves into the intricacies of MFI, measurement techniques, and relevance in the polymer industry, all while highlighting its significance.The Melt Flow Indexer is a highly precise instrument specifically designed for measuring the melt flow rate (MFR) or melt index (MI) and melt volume rate (MVR) of thermoplastic materials. Its primary purpose in both quality control and research applications is to assess plastic viscosity, flowability, and processing behavior under specific .

The melt flow index measurement is a standardized test method to characterize the flowability of plastics at a defined temperature and constant force with a plastometer. A thermoplastic material is melted in a heated test barrel. The application of a .

MFI testing ensures these materials meet the necessary criteria. 4. Electronics: The electronics industry utilizes MFI testing for materials used in cases, connectors, and insulating components. How to Use a Melt Flow Index Tester Using a Melt Flow Index Tester may seem intimidating, but it can be broken down into a few simple steps:As we have already discussed above, the melt flow index tester will comprise piston assembly with a heated barrel that will be helpful in storing sample. You can calculate the melt index flow with the help of the melt index flow formula. This testing instrument will be helpful in checking the quality of materials used in finished products.Benefits of Melt Flow Index Testing. Melt Flow Index Testing is a common method used to evaluate the flow properties of a thermoplastic. The Melt Flow Index is a measure of the ease with which a material flows and is determined by measuring the rate of extrusion of a molten polymer through a capillary die under specific conditions. Melt Flow .

The melt flow test (also referred to as melt index test or melt flow index test) is a test method used to determine the flow properties of thermoplastic materials. The test measures how much material flows through a standardized die while .The determined value is given as Melt Flow Rate (MFR) in g/10min or as Melt Volume Rate in cm 3 /10min. The test temperature and the load weight are always indicated with the result on the and depend on the material. The following table shows, for a selection of materials, the test weight and test temperature we recommend for performing the .

In plastics manufacturing, the melt flow index (MFI) is used as a routine indicator of rheological behavior when more expensive and laborious determinations of well-defined material functions are impractical. The MFI is the mass flow rate in a pressure dr . software installation or testing, loading new files, and reasons beyond the control of . Melt flow testing is simply a measure of the flow of a polymer when melted. The result of a melt flow test, called the melt mass-flow rate (MFR) or melt volume-flow rate (MVR), is defined as the amount of mass or volume of a polymer that flows through a small die at a specified temperature and pressure.

The melt flow Rate (MFR), originally called Melt Flow Index or Melt Index, is a measure of the ease of flow of the melt of a thermoplastic polymer. MFR is a mass flow expressed (SI units) in g/10min, which is defined as the mass of polymer, in grams, flowing in ten minutes through a capillary of a specific diameter and length by a pressure . The Melt Flow Index test originated in the labo- ratories of ICI, in the early stages of development of . polyethylene, and was mainly used in the past for . World's leading supplier of rheological material testing machines in the field of plastics and rubbers • Melt Flow Indexer • Capillary Rheometer • MDR/RPA Elastomer Tester • Online Rheometer • Laboratory Extruder • Full Rheological Test Systems • serviceCONNECT • Remote Support • inars . Melt Flow Index Instruments .

Abstract. In plastics manufacturing, the melt flow index (MFI) is used as a routine indicator of rheological behavior when more expensive and laborious determinations of well-defined material functions are impractical. The MFI is the mass flow rate in a pressure driven flow through a standardized abrupt cylindrical contraction into a short tube performed under a . Limitations of Melt Flow Index Testing While MFI testing provides valuable insights, it also has limitations: Single-Point Measurement: MFI is a single-point measurement and does not provide information on how viscosity changes with shear rate. Rheological testing might be needed for more comprehensive analysis. The melt flow index (MFI), also known as the melt flow rate (MFR), determines the melt flow properties (measured in g/10 min) of a material at a specific shear stress (related to applied load) and temperature. . •ASTM D1238: Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer, •ISO1133: Determination of the .

Melt Flow Index (MFI) is a measure of the mass of a polymer that flows through a specified capillary under controlled temperature and pressure over 10 minutes. Typically expressed in grams per 10 minutes (g/10 min), MFI is measured using a melt flow indexer or extrusion plastometer. . Standards for MFI Testing. The most common standards for .

Oxygen Water Vapor Transmission Rate Test System inc

plastic melt flow index chart

WEB28 de nov. de 2022 · The Moulin Rouge is probably the most famous cabaret show in Paris, founded in 1889 at the heart of the Montmartre district. The Crazy Horse is a temple to the female form, a place with its own mythology that celebrates the nights when the City of Lights becomes the City of Delights.

melt flow index testing|melt flow index table